26th International Conference on Electrical Machines (ICEM 2024) Review

By Paul Fears | 16 September 2024

The 26th International Conference on Electrical Machines (ICEM 2024) brought together academia and industry on a scale previously unseen. The growth in industry participation reached 50% of all attendees in 2024 and the number of exhibitors reached record levels, highlighting the ever-growing importance of electrical machine technology.

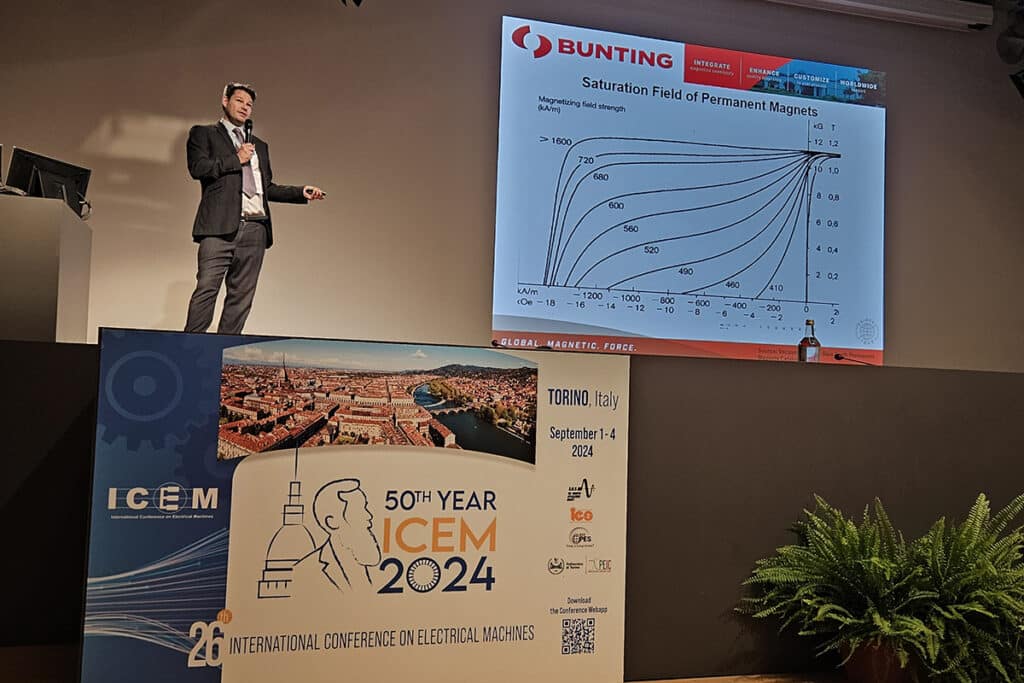

The International Conference on Electrical Machines (ICEM) has established itself as an influential and recognised international event, being the only major international conference entirely devoted to electrical machines. Started in London in 1974, ICEM is now established as a regular event. The 2024 event was held in Torino, Italy in September.

“The importance of electrical machines has never been greater,” explained Matthew Swallow, Bunting’s Technical Product Manager. “The proliferation of electric vehicles, green energy technology, and a focus on energy efficiency is driving research and development.”

Matthew was one of six specialists presenting keynote addresses and he explained the benefits of Bunting’s manufacturing techniques to post magnetise complex magnet assemblies after build completion.

In his address, Matthew explained the reason behind developing post-assembly magnetising techniques. “The aim was to simplify the manufacturing process and improve safety. Complex magnet assembly are difficult and dangerous to construct with charged magnets, especially high-energy permanent magnets such as neodymium iron boron. Our focus was building the assembly with uncharged magnets, which were then charged once the build is fully or partially complete.”

There are many advantages to post-assembly magnetisation. Constructing the magnet assembly is easier and the time is taken shorter. There is also a reduced risk of mistakes occurring during assembly (e.g. incorrect polarity orientation). Post-magnetisation means that the polarity and magnetic field are exactly as required for every magnetic component. This type of component consistency is ideal for critical applications in the automotive and aerospace sectors.

“Bunting is the only company with expert knowledge of both permanent magnets and magnetising equipment,” explained Matthew. “We are working with companies in the design and build process of complex magnet assemblies and the magnetising equipment needed to charge those assemblies. It is a complete solution that enables the repeated production of a magnet assembly that meets a critical specification.”