Grain Boundary Diffused (GBD) Neodymium magnets are the most powerful magnets currently available. They are the premium choice for maximum performance.

Grain Boundary Diffused magnets employ a secondary manufacturing process to concentrate the Heavy Rare Earth Element Dysprosium into the grain boundaries of the magnet microstructure, hence the name. This not only nets a performance increase but uses less Dysprosium making them more price stable than traditional method magnets.

All GBD Neodymium NdFeB is REACH and ROHS compliant and does not contain SVHC’s whilst licensed grades are produced to ISO9001 and ISO14001 Quality Control Standards. Certificates of Conformity, MSDS and PPAP’s can be supplied on request.

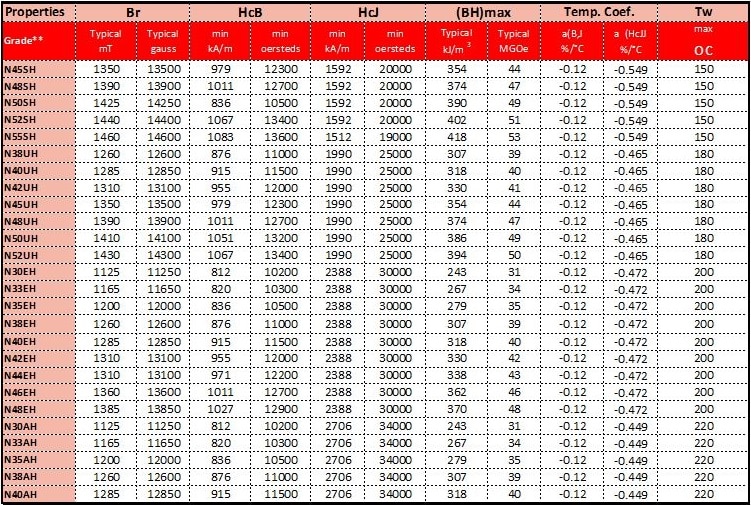

GBD Neodymium grades exist with the maximum recommended temperature ratings - from +60°C up to +230 °C but these ratings are GUIDELINE values only. The actual maximum temperature rating depends on the shape of the magnet and the design of the application. GBD magnets are limited in thickness to 8mm, and certain grades are not available with some magnet geometries.

Please contact us for the highest available grade in your magnet design.

Exceeding the actual maximum temperature results in a permanent demagnetisation (a permanent weakening of magnetic output) which is only recoverable by re-magnetisation. All Neodymium NdFeB grades require a protective coating to prevent and minimise corrosion. The coating is usually a Ni-Cu-Ni plating although other coatings/finishes exist. Neodymium NdFeB magnets can be made in blocks, discs, rings, arcs, spheres, triangles, trapezoids and many other shapes. Certificates of Conformity, MSDS’s and PPAP’s can be provided on request.

Please call or contact us for your specific requirements or any technical assistance. All customer-specific Neodymium magnets are inspected at our UK magnetic inspection facility. For full details of our capabilities visit www.bunting-berkhamsted.com/magnets-experts/

Downloads - Grain Boundary Diffused Magnets Datasheet