Magnetiser Reaches 1.29 Million Discharges

By Paul Fears | 31 January 2022

In 1997, Bunting’s Group Magnetics Engineer Chris Riley commissioned a 30kA 4kj Magnetiser at Bunting’s European magnetic manufacturing and design headquarters in the UK. The bespoke Magnetiser charged a range of specialist magnets and magnet assemblies.

Since the original installation, Bunting’s engineering team has annually serviced and calibrated the Magnetiser. Such a proactive approach to maintaining the performance of a magnetiser ensures that key component parts are proactively replaced.

- Technical product information: Magnetising Equipment

Regular Calibration and Servicing

Regular Magnetiser calibration identified when capacitors aged, with a reduction in the peak capacitance. These were then replaced, well in advance of the magnetic field falling below the minimum requirement for charging and discharging in a range of multipole magnetising fixtures.

Annually servicing and calibrating the Magnetiser initiated the regular replacement of worn or high-use components. This proactive approach extended the operating life of this this ‘Grand Dame’ of Bunting Magnetisers, which was decommissioned in 2022 after operating for 25 years.

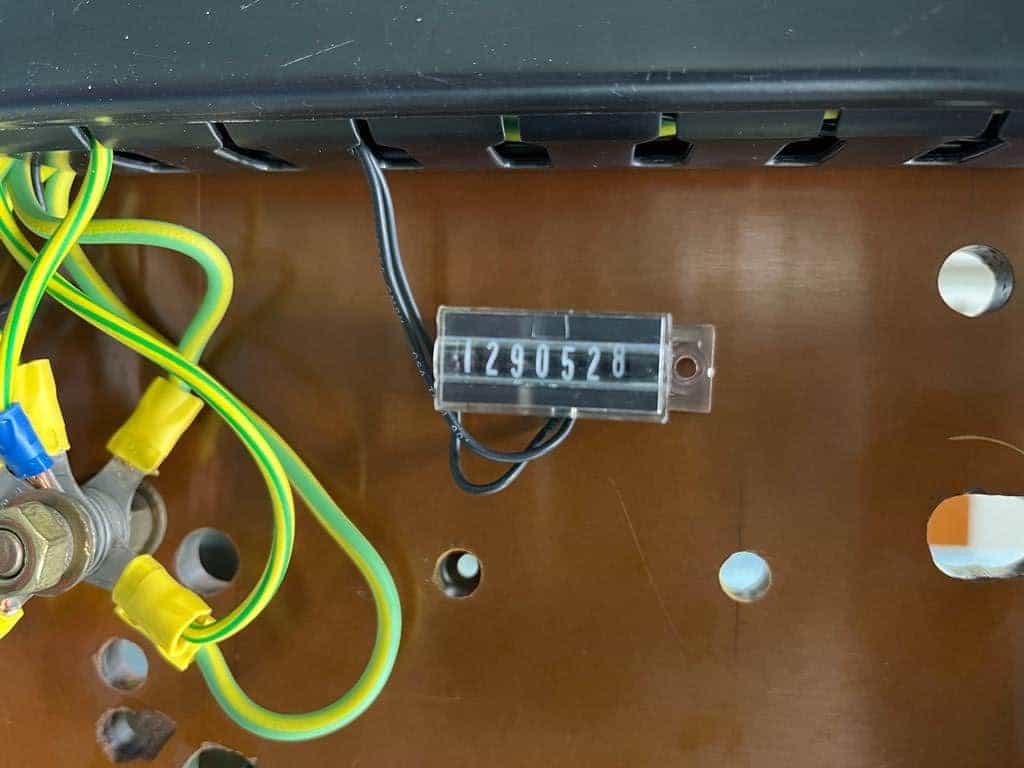

During the decommissioning some components were saved to support other machines in the manufacturing facility. Also, our engineers uncovered the pulse counter, which had been hidden away behind a fire board. The pulse counter records the number of times a magnet or magnet assembly had been charged and discharged. The data showed that the 25-year-old Magnetiser had reached 1.29 million discharges, which averages out at 1,000 per week over the 25-years.

9 Million Discharges in 2 Years

Although sounding impressive, A dual magnetiser system presently holds the current record for the number of discharges, firing every 6 seconds, for 24 hours a day, 6 days a week. Supplied in 2020, this Magnetiser will reach nearly 9 million discharges in 2022. Once again, such an intense operating life is made possible by following a strict maintenance programme, whilst holding critical spares and regularly changing magnetising fixture changes.

Nevertheless, for both projects, it is the original Magnetiser design which has ensured that longevity of optimum performance.

Related Technical Articles

Magnets, Magnet Assemblies and Magnetising Equipment

Bunting designs, manufactures and supplies a wide range of magnets, magnet setters, magnetisers, and magnet assemblies. Many are bespoke for specific applications. For further information on any of the products mentioned in this article, or for bespoke magnet assemblies and magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology

Follow us for all our latest news on Social Media