Bunting Sponsors Electric & Hybrid Aerospace Technology Virtual ‘Live’

By Paul Fears | 24 February 2021

The future of electric and hybrid aircraft technology is the focus for presenters and delegates at the Electric & Hybrid Aerospace Technology Virtual ‘Live’ conference (April 20 & 21, 2021). The 2-day online event provides a platform for aerospace engineers, research academics, aircraft manufacturers, others working on developing this ultra-low-emission, ‘green’ transportation technology.

The move towards the electrification of transportation continues to gather momentum. Political and environmental pressure is driving the development of the technology, with many aerospace experts predicting that the future of flight is electric.

During the 2-day conference, aerospace experts will discuss the move toward more electric aircraft with a focus on the introduction of hybrid and full electric propulsion technologies.

Magnetic Technology for Electric & Hybrid Aerospace Technology

Bunting is one of several companies sponsoring the conference. As a world-leading supplier and designer of magnets, magnet assemblies and magnetisers, Bunting is already involved in the design and development of key components and new manufacturing techniques for the aerospace and automotive sectors.

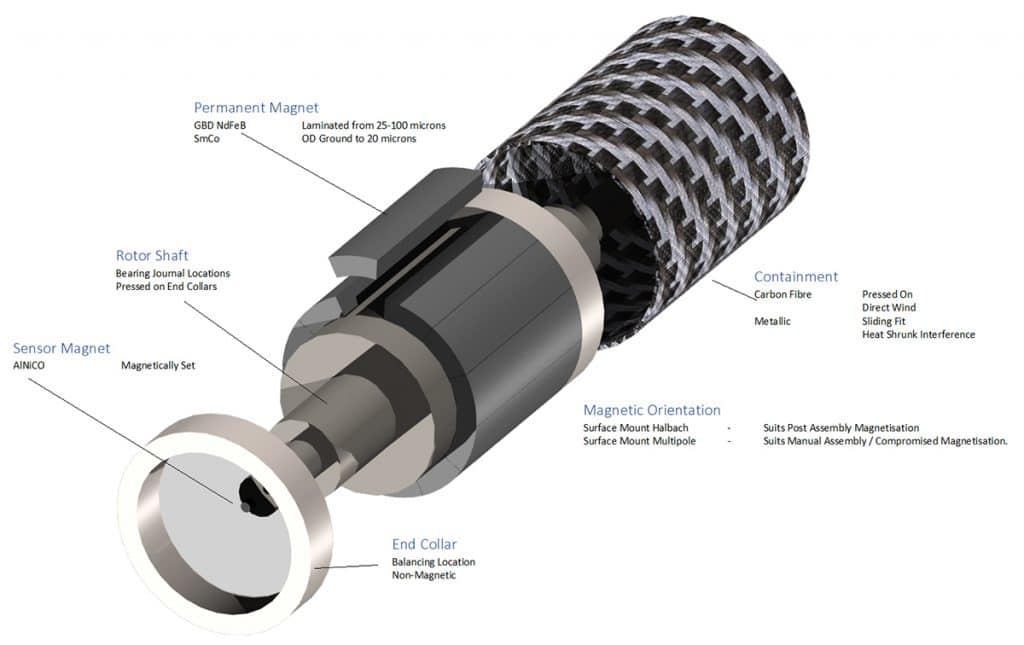

At the conference, Dr. Chris Riley, Group Magnetics Engineer, discusses the benefits of post assembly magnetisation of magnetic rotors. With the aim of simplifying the manufacturing process and improving safety, Bunting’s technical engineering team developed technology for post-assembly magnetisation. Subsequently, a complex magnet assembly is constructed unmagnetized and then charged.

- Technical product information: Magnet Assemblies

There are many advantages to post-assembly magnetisation. Constructing the magnet assembly is easier and the time taken is shorter. There is also a reduced risk of error occurring during assembly (e.g., incorrect polarity orientation). Post-magnetisation means that the polarity and magnetic field are exactly as required for every magnetic component. This type of component consistency is ideal for the aerospace sector.

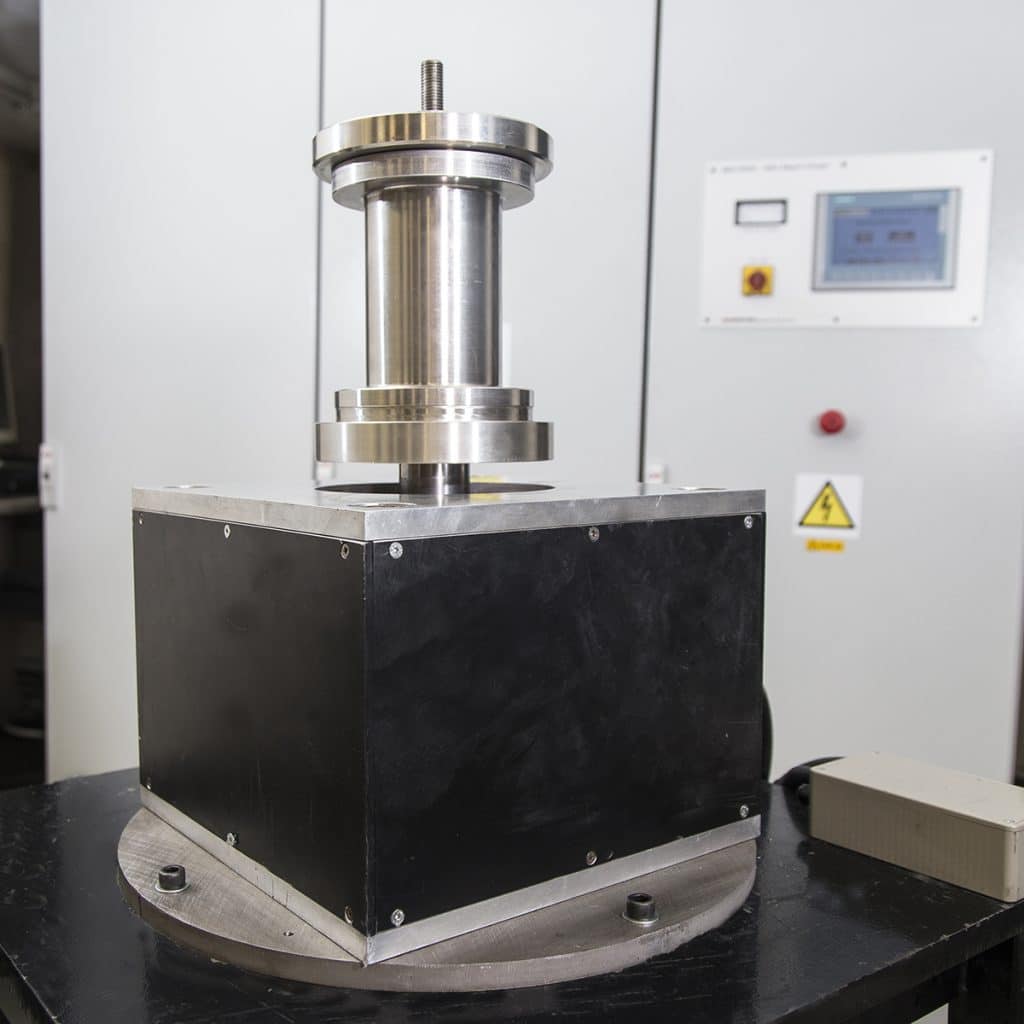

The associated Magnetising technology enabling post-assembly magnetisation comprises of a complex control and power supply with a magnetising fixture. Such Magnetisers enable post-assembly magnetisation of magnet assemblies including Halbach Arrays, Surface Mounted Magnet Rotors, and IPM Motors.

Bunting’s range of Magnetisers include bench-top and laboratory scale models (BMLC Series) for lower volume batches of magnets and magnet assemblies, with Industrial Magnetisers (BMC Series) for higher energy demands of the some of the more complex industrial applications (such as the 150kJ multi-cabinet 5kV system). All the Magnetisers are PLC-controlled with fixture temperature monitoring and HMI interfaces.

- Technical product information: Industrial and Bench-Top Magnetisers

The Bunting engineering team also design bespoke magnetising fixtures for specific customer applications. In a typical application, the magnetising fixture enables the production of high homogeneity bonded-neodymium magnetic fields for applications including rotating field measurement and multipole sensors. The range of magnetising fixtures is extensive to suit the diverse types of magnetic fields, magnets and magnet assemblies. Designs include Internal Radial Multipole Fixtures which produce a multipole radial field on the internal diameter of a ring magnet or magnet assembly such as the rotor of an exterior rotor permanent magnet machine, permanent magnet stators or flywheels.

Related Technical Articles

Bunting designs and manufactures a wide range of magnets and magnetic assemblies. Many are bespoke for specific applications. For further information on any of the products mentioned in this review, or for bespoke magnet assemblies and magnet designs, please contact us via:

Phone: +44 (0) 1442 875081