Magnet Technology

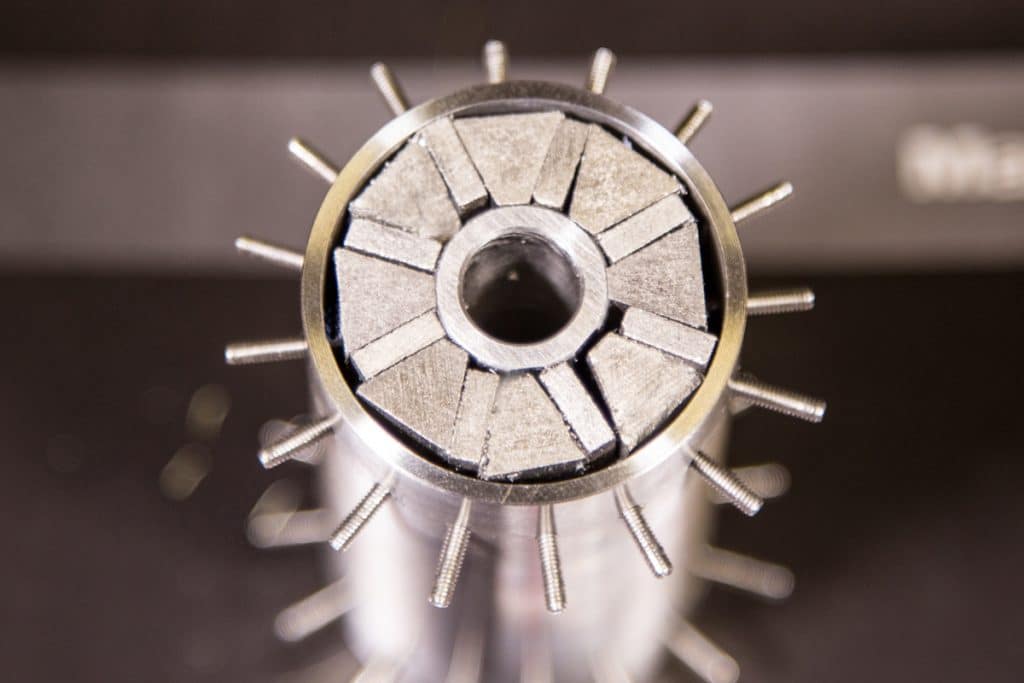

Magnetising Fixture Winding for Magnet Ring Sensor Project

Bunting’s engineering team work with companies on many magnet product designs, from concept through to manufacture. This project focused on the feasibility of designing, manufacturing, and supplying a permanent magnet ring to produce a sinusoidally varying flux density waveform for a sensor application. A sine wave or sinusoid is a mathematical curve that describes a…

Read MoreBunting Magnet Test and Development Centre Investment

Bunting has invested in expanding their Test and Development Centre at Berkhamsted in the UK where they specialise in the design, test and build of a wide range of magnet and magnetic technologies. Bunting’s Berkhamsted operation is responsible for the design and manufacture of magnets, magnet assemblies, and magnetising equipment. The range of applications for…

Read MoreExhibition Success for Bunting-Berkhamsted

Exhibiting at two shows, in different parts of Europe, over the same two days, was challenging for the Bunting-Berkhamsted team, but proved exceptionally successful. Whilst Matthew Swallow managed the stand at the Cenex LCV event at UTAC Millbrook in the UK, Stefano Maiaroli and Dr Chris Riley were in Pordenone in Italy at the Coiltech…

Read MoreMagnetics Importance for Electric Vehicles at Cenex-LCV

Magnets and magnet assemblies, both essential for transport electrification, are the focus for Bunting on stand C4-106 at Cenex-LCV (UTAC Millbrook Proving Ground, Bedfordshire, UK, 23rd to 24th September 2021). In particular focus is the technique of magnetizing magnet assemblies after construction, which offers a wide range of benefits including accuracy and safety. The LCV…

Read MoreMagnetiser and Magnet Setter Export Success

Successful implementation of an overseas business development strategy has resulted in orders from Italy for a bespoke Industrial Magnetiser, complete with control cabinet, and a Magnet Setter. Bunting’s UK engineering design team will design, build and test the magnetisers, control and magnet setter. Industrial Magnetisers and Magnet Setters enable the charging of both permanent magnets…

Read MorePermanent Magnet Motors Providing Key Benefits

Permanent magnet motors are electric motors using permanent magnets in addition to windings. Such motor designs are more efficient than induction motors or motors with field windings for certain high-efficiency applications such as electric vehicles and small electric motors such as found on drones and in car windshield wipers. Both AC and DC motors benefit…

Read MoreEverlube Coating Protects Neodymium Magnets

The new Everlube anti-corrosion magnet coating combats the increasingly arduous working environments for magnets and magnetic components. The Everlube coating prevents oxidation and deterioration of high-powered permanent neodymium rare earth magnets. The Everlube coating was originally developed as a brand of dry film lubricant products specifically designed to enhance and improve the performance of critical…

Read MoreAn Introduction to the Halbach Array

Halbach Arrays feature in many common-day devices such as brushless DC motors and even the Inductrack Maglev train. The Halbach Array is a specific arrangement of permanent magnets that cancels the magnetic field to nearly zero on one side, but significantly increases the strength of the magnetic field on the opposite side. This magnetic phenomenon…

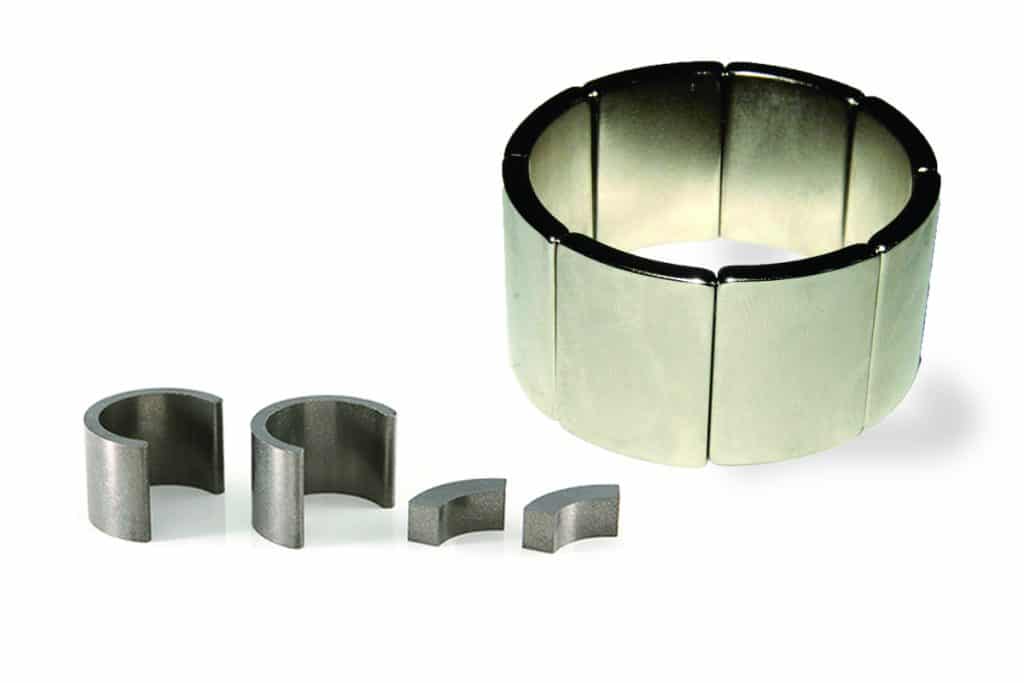

Read MoreSurface Mounted Arc Magnets

Bunting is capable of supplying almost any shape and size of a permanent magnet, but one of the most popular shapes is the arc. Arc magnets are used in a wide range of magnet assemblies, but in particular, surface mounted electric machines. There are four main types of arc magnets and these are: Each arc-type…

Read MoreBespoke Pot Magnet Design for Oil and Gas Application

An international Oil and Gas company turned to Bunting when investigating designs for a novel magnetic system to act as a pressure relief valve. The Pot Magnet assembly design requirements were complex with a number of significant technical challenges. The initial design evaluation identified that the bespoke magnet assembly would be based on a simple…

Read More