Ever Increasing Rare Earth Metals Demand

By Paul Fears | 07 March 2018

Technology Driving Up Rare Earth Magnet Prices

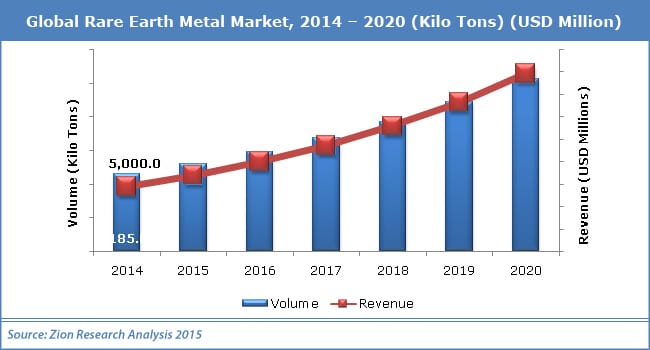

The global market for rare earth metals will be worth an estimated US$ 7362 million by 2026, according to Future Market Insights. This projection equates to a compound annual growth of 8.5%. The growth in demand is expected to put pressure on prices.

The vast majority of Rare Earths are mined in China, where there are 36% of the world’s estimated reserves. Changes in pricing can be political, as can restrictions on mining and exports. As well as being the leader producer, China is also the leading consumer of Rare Earths.

The Rare Earth suite of elements includes Neodymium, Lanthanum, Cerium, Praseodymium, Gadolinium, Yttrium, Terbium, and Europium. Neodymium has been used used in the manufacture of high strength magnets since 1982. With technological developments, Neodymium Magnets have got stronger.

Neodymium Applications

The demand for Neodymium continues to grow at a high rate. In 2016, Neodymium accounted for 38% of sales of all Rare Earths and this is not expected to change. Neodymium is used to make powerful Rare Earth Magnets that are used in loudspeakers and computer hard drives. Neodymium Magnets are also used in green technologies such as the manufacture of wind turbines.

Neodymium also is one of several Rare Earth Elements (along with lanthanum, cerium and praseodymium) used as the intermetallic compound that forms the negative electrode in a NiMH battery used increasingly in hybrid and electric vehicles.

Future Demands

Once charged, high strength Neodymium Magnets do not need any power. Subsequently, many product designers are aiming to harness this ‘free energy’. Also, the global move towards electric transportation, where Rare Earths play a vital role in battery development, is expected to drive up the demand.

The scope of potential applications for magnets is huge. The only negative is whether it is possible to meet demand. Projects such as the EU-funded SUSMAGPRO project are focusing on developing techniques to successfully recover, reuse and recycle rare earth magnets from electronics, vehicles and other technology. This follows the European Union identifying the risk of continued reliance on Chinese supplied rare earth metals and magnets.

Related Technical Articles

- Rare Earth Magnets in Electric Vehicle Motors

- SUSMAGPRO Rare Earth Magnets Recycling Task Force

- Bunting Introduces Carbon Neutral Neodymium Magnets

Magnet and Magnet Assembly Design

Bunting designs, manufactures and supplies a wide range of magnets, magnet setters, magnetisers, and magnetic assemblies. Many are bespoke for specific applications. For further information on any of the products mentioned in this article, or for bespoke magnet assemblies and magnet designs, contact us via:

- sales.berkhamsted@buntingmagnetics.com

- call us on 01442 875081

- Via the website