Replicating True Radial Arc and Ring Magnets with Pseudo-Radial Arcs and Rings

By Paul Fears | 15 June 2020

The manufacture of anisotropic radially magnetised arcs and rings is significantly different to the production of diametrically magnetised rings and arcs. Radially aligned and magnetised anisotropic arcs and rings are only possible in fully dense sintered NdFeB and need a dedicated press tool and magnetising fixture and have a limited physical envelope (Max OD 85mm). Other true radial alignment is possible in all isotropic magnet materials, using both bonded and sintered structures.

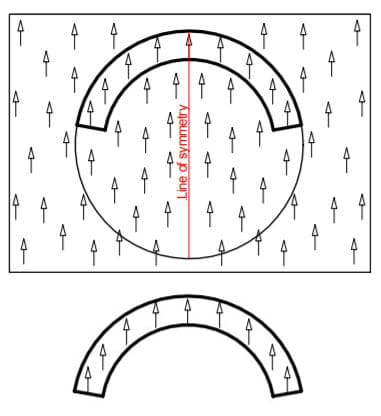

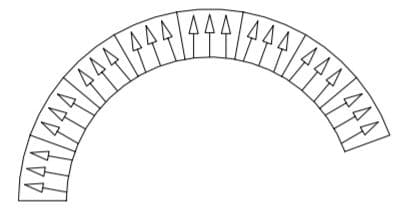

The majority of permanent magnets are produced with a single direction of magnetisation where the lines of flux within the magnetic material are parallel (e.g. axially magnetised disc and rod magnets, block magnets). Arcs are cut from blocks of manufactured magnetic material. Note the standard direction of magnetization, as shown by the arrows in figure 1.

This direction is fixed into the structure during manufacture of the block (the block is pressed to shape in the presence of an external magnetic field that is produced by a solenoid surrounding the block). This method is a standard practice. The cut arc therefore shares the same direction of magnetization as the block.

In figure 1, the arc has been cut so that the direction of magnetisation of the magnet is parallel to the line of symmetry of the magnet. This is defined as ‘diametrically magnetised’. The standard direction of magnetisation within such cut arcs is diametrically magnetised.

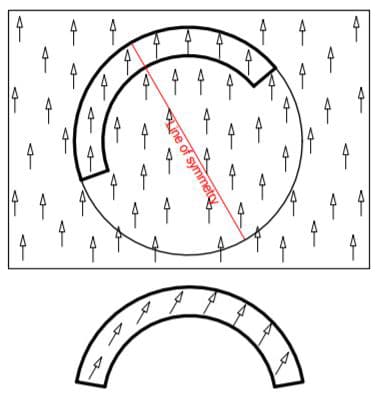

If the arc was rotated around by a defined angle, the direction of magnetisation is also rotated around by the same defined angle, as shown in figure 2. This is particularly useful for designs such as Halbach Arrays.

True Radial Arcs and Rings

As previously highlighted, true radial arcs and rings either require tooling to produce or may not be possible because of the size requirements of the system. For very low volume prototypes and where the size needed is larger than the tooling can produce, then the best option to create a radial field in large arcs or in rings is to utilise a high number of very small angle arcs. As before, when considering the complete system, assembling 360 magnets at 1 degree arc is considerably more difficult than a single ring.

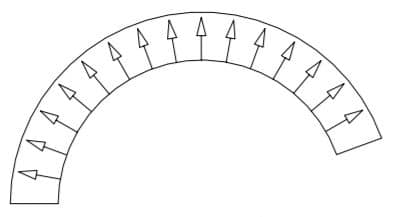

The alternative to a pure field created by 1 degree arcs is to use larger diametrically magnetised arcs to replicate a radially magnetised arc or ring. Hence the name Pseudo Radial as there is now a significant difference in the ultimate magnet field generated.

Making Pseudo Radial Arcs and Rings from large angle diametrically magnetised arcs

angle diametrically magnetised arcs

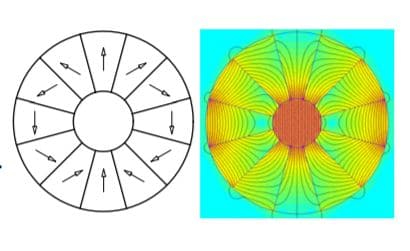

When using diametrically magnetised arcs segments of large angle, a magnetic pattern in the completed arc and ring starts to mimic a desired radial pattern. The effect may be cruder if large angle arcs are used but assembly time is relatively fast. Forty degree arcs are shown in figure 4.

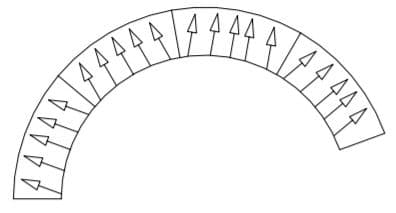

Making Pseudo Radial Arcs and Rings from small angle diametrically magnetised arcs

angle diametrically magnetised arcs

When using diametrically magnetised arcs segments of small angle, a magnetic pattern in the completed arc and ring starts to mimic more closely the desired radial pattern. The effect may be improved if even smaller angle arcs are used, although this increases the assembly time. Despite not producing a perfect radial pattern, the finished arc meets the specification requirements for the application. Twenty degree arcs are shown in the figure 5. If a pure radial array is required multiple rings stacked axially with each ring being rotated relative to the next can improve the pseudo-radial magnetic wave-shape even further.

Special use of arc magnets – the Halbach Array

When using arcs where the direction of magnetisation is set to different angles, a Halbach Array can be produced, giving a highly uniform (homogeneous) magnetic field in the air gap. The field strength in the air gap can also be very large (e.g. over 1 Tesla / 10000 Gauss).

- Product information: Neodymium Halbach Array

Bunting utilise this technology to produce bespoke Halbach arrays based upon a number of key criteria including:

- Outer diameter;

- Inner diameter;

- Lengeth;

- Magnetic field required

- Any other application specification

Related Technical Articles

Bunting design and manufacture a wide range of magnets and magnetic assemblies. Many are bespoke for specific applications. For further information on bespoke magnet assemblies, magnet designs and Halbach Arrays, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology