Ryan Haig-Godden Reflects on MMA24

By Paul Fears | 10 December 2024

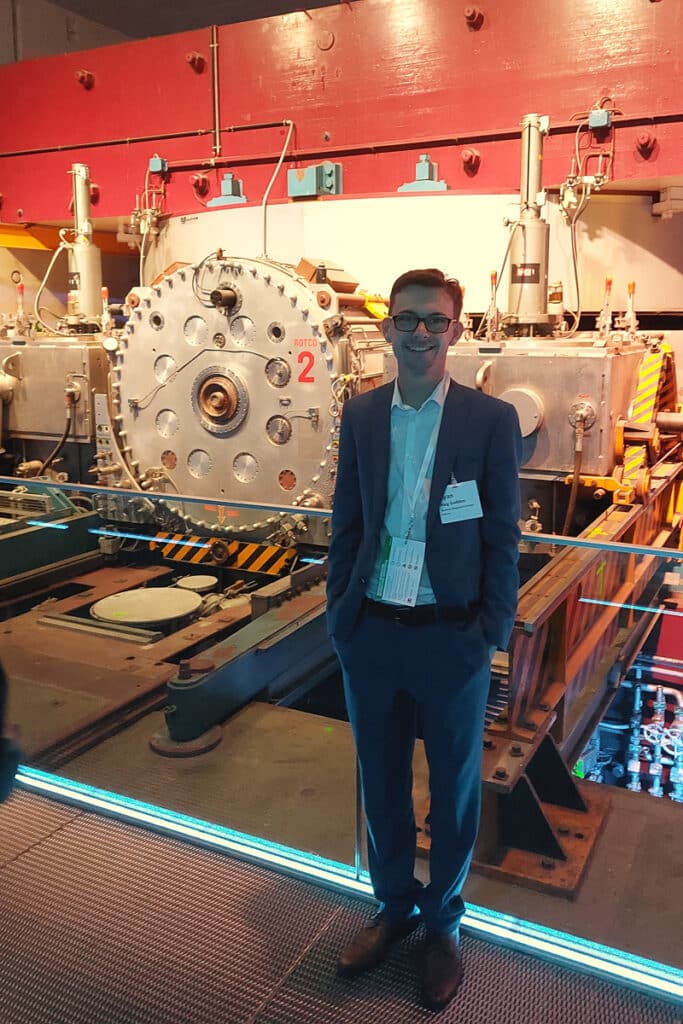

Ryan Haig-Godden, Bunting’s Development Engineer, reflects on a memorable visit to CERN in Geneva, Switzerland, while attending the event of the UK Magnetics Society’s Magnetic Materials and Applications 2024.

“In 2018, if someone had told my eighteen-year-old self that in 2024 I would not only get to go to CERN, but I would go representing the company which I had just joined as an apprentice, I really wouldn’t have believed them. When I started with Bunting I never considered being asked to attend such an event, never mind having an appreciation and understanding about what the various talks were about. And yet, here I am, a few weeks after the MMA24 and I don’t think I will forget that I went to CERN for a conference with work, as part of my job!

CERN is the European Organization for Nuclear Research. It is a massive particle physics laboratory on the French-Swiss border. There are various experiment sites and detectors spread around its site and the 27 km Large Hadron Collider (LHC). The LHC uses superconducting magnets to bend the trajectory of particles around the ring as they are accelerated. The stronger the magnetic field which can be achieved with these magnets, the higher the energy of the particle beam. So, CERN and the LHC have large ties with magnetism.

Across the two and a half days at the event, we had the privilege of talks ranging from the opening address by Mike Lamont from CERN to hovering steel over permanent magnets by Doug Craigen from Integrated Engineering Software to the magnetic field cameras of Magcam. Here are some brief points from those I found the most exciting or interesting (all the talks were fascinating!) in relation to me and my job:

Mike Lamont’s Opening Address

The opening address by Mike Lamont was fascinating. As a Physics BSc student, any information about the work being done at CERN is exciting to me, and this year, 2024, marks the 70th anniversary of the CERN organisation. I was somewhat surprised about how similar some of the challenges being faced by CERN mirror those faced by Bunting. While this is a big simplification in my head, the magnets being manufactured and used around the LHC are like massive cryogenic versions of the multipole magnetising fixtures which we are making in our manufacturing plant at Berkhamsted. At CERN they run for significantly longer periods of time, are comprehensively larger (in total field volume), and are kept at vastly colder temperatures, but the basic concepts and goals are very similar. When dealing with high energy beams of particles, it is important to have as uniform magnetic field as possible to help bend or focus the beam. This is the sort of challenge we have when designing and manufacturing some permanent magnetic assemblies.

The Small 3D Hall Probe from SENIS

The talk given by Dragana Popovic Renella from SENIS was on the products they offer and their small 3D hall probe. I had previously used a SENIS magnetic scanner so for me much of this talk was spent thinking about other ways I could apply or use SENIS products to my workflow or to help with challenges we face. SENIS offer a fantastic resolution on their scanners, which currently is unnecessarily precise for the typical projects we are dealing with, but it is eye-opening to see that the potential for increased precision is there. I had previously not appreciated the importance of working to reduce the size of the 3D hall sensor, with a smaller sensor meaning that the region which is being measured and averaged across is also smaller.

Developing Magnetic Material Standards

Stuart Harmon from NPL (National Physics Laboratory) gave a talk on developing magnetic material standards. Before the talk I knew of uncertainties in the form of engineering tolerances and measurements as taught in university, but I did not know or appreciate how important they are to minimise when attempting to define standards of measurement. When it is considered how these uncertainties stack up across the different stages of industry is really isn’t surprising. The repeatability of measurements is also very important, as are calibrations of equipment and measuring devices. Once again, these echo what I am learning at university, as is the importance of collaboration within the STEM industries.

SI Standards and the Magnetic Calibration Chains

Franziska Weickert from PTB (Physikalisch – Technische Bundesanstalt, the National Metrology Institute of Germany) gave a talk on the SI standards of the Tesla and the magnetic calibration chains. This intriguing talk was about how nuclear magnetic resonance can be used to measure the magnetic field through the relaxation times of helium. This talk also included a graph of how the earth’s magnetic field changes across a period of a week. It is relatively consistent with a typical change across a day of around 45 nT, with a minimum each day around midday. Also, the earth’s magnetic field is susceptibility to change through the effects of space weather, which can cause changes on the order of 1 µT. Franziska reemphasized the importance of minimising uncertainties through the chain of industrial standards. The talk referred to the magnetically shielded room at their facility, which has been calibrated down to ± 100 pT, which I find genuinely astonishing. This is equivalent to ±1 microgauss!

Repulsive Magnetic Forces

As I mentioned earlier, the talk from Doug Craigen’s, from Integrated Engineering Software, looked at how the magnetic forces on steel parts near a magnet can become repulsive. It is interesting to learn that they first noticed this odd behaviour in the results of a simulation, which then lead them down the path of further analysis and physical prototyping looking for larger, more stable regions of equilibrium. This sort of ‘scientific playing’ really resonates with me as I try to understand and interpret the results of my own FEA simulations. A small rule of thumb that I was able to take away was that the force on magnets is proportional to the magnitude of the gradient of the magnetic field which they are in, while the force on steel is proportional to the magnitude of the external magnetic field.

Additive Manufacturing of Permanent Magnets

From the second day of talks Ester Palmero from IMDEA Nanociencia gave a very interesting talk on the additive manufacturing of permanent magnets. The idea of using 3D printing to manufacture permanent magnets has the potential to open many possibilities of magnet design. The easiest of these which I can think of is the rapid prototyping of magnet designs. While the direction of magnetism of these rapidly printed magnets may be limited to simple orientation, this may still enable the production of test articles much faster than getting them manufactured through the traditional routes. The magnets produced in this manner are inherently isotropic, and with their relatively low magnetic material by mass, they are going to be weaker magnets than the traditional magnets. The talk spoke about the difficulties of formulating an appropriate printing medium to be used in the manufacturing; what polymers to use, the amount of magnetic material, and the size of the magnetic materials within the printing medium, etc. This is an area of research and development which I will be keen to see how it develops and get my hands on at some point.

Open-Loop Pulsed Field Permeameter

The talk from Luc Van Bockstal from Metis on their Open-Loop Pulsed Field Permeameter was interesting due to the specification of some of their equipment. While there are lots of differences between their product goals and ours at Bunting, comparing the required energies for fields is interesting. According to the presentation, 28 kJ is needed to reach 7 T across a 50 mm diameter. Through some quick calculations based on past test data, we would need 25 kJ to achieve the same field over a slightly larger diameter. This is reassuring as it highlights our ability to use the energy available efficiently. It is hard to make a direct comparison as the total volume which experiences a field of 7 T is not known for the Metis system.

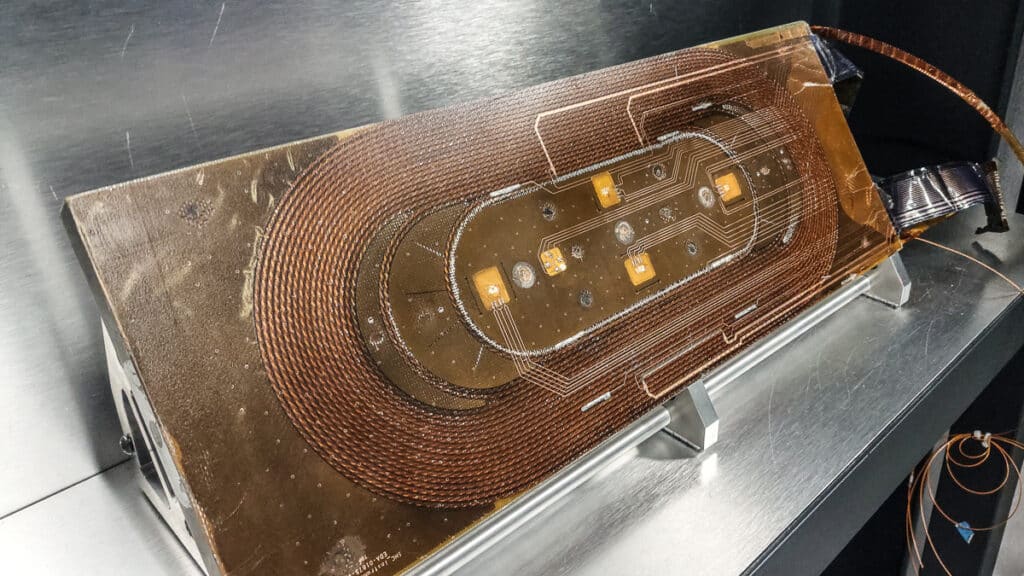

Chris Riley Discusses Post-Assembly Magnetisation

One of the final talks of the day was from one of Bunting’s Group Magnetics Engineer, Chris Riley. This talk was on High Field Post Assembly Magnetising. Given I work closely with Chris much of what was presented was known to me in some level already. Working with the challenges of magnetising forces is something that we are spending more and more time on understanding and reducing. This presentation did however contain one of my top highlights of the event, seeing one of my thermal simulations up on the presentation screen. As someone still early in their career, with aspirations of one day standing at the front giving a fascinating talk like those before me, seeing my work on display like this, at such a prestigious location (CERN) has filled me with a further level of drive to progress my knowledge and to push what we can achieve.

Tours of CERN

Across the event we were given multiple tours of different facilities around CERN, from visiting the decommissioned Synchrocyclotron, the Large Magnet Facility, a cryogenic test facility to the facility which manufactures the testing equipment for the superconducting magnets. Each facility was amazing in its own respect, and many of the manufacturing techniques in place at CERN are like those we have at Bunting (in principle, not scale).

While walking around one of these sites there was an LHC sextupole on display. This is used to correct the beam orbit around the LHC, and this small multipole fixture looks very similar to those which we manufacture for magnetising multipole magnets (a bit bigger however). Also on display was cross-sections of the magnetic quad-poles which show how much reinforcement is needed to prevent the conductors from moving and deforming under the immense electromagnetic forces they are under.

In the Large Magnet Facility, where they manufacture the new coils for the LHC, there is a large vacuum pressure tube to allow the resin impregnation of windings. The have a large press to impart a 9 mm curve to the 10 m long magnets, this seems like such a small curve but when dealing with the precision which they are at the LHC, this is very important. According to the tour guide they press down to 15 mm to have the magnet spring back to the required shape. Both examples of manufacturing processes are like those which we undertake for many of our magnetising fixtures.

All the tours and talks which I have not mentioned were interesting in their own right, each with each something that related to me and my work. A small part in the back of my brain is now thinking “hmm, could I build one of them?”. This shows how insightful and relatable a lot of the tours and speakers were.

It was an absolute privilege to be given the opportunity to attend an event like this and I would like to thank Bunting, Chris Riley, Matthew Swallow, all the speakers, the UK Magnetics Society, and everyone at CERN.”